材料:Q355B

主要参数

编号 :

CX800支付 :

TT产品产地 :

China Fujian装运港口 :

XIAMEN交货时间 :

30days挖掘机打桩臂及吊臂

这 CX800 打桩臂 是一种专为重型桩基工程而开发的解决方案。 凯斯CX800(约80吨级) 专为在大规模、高负荷基础环境中可靠运行而设计的挖掘机。

这种打桩臂适用于需要以下条件的项目: 深桩贯入和长时间振动作业, 例如 桥梁基础、港口建设、河岸加固、近海或离岸桩基工程以及大型光伏桩基安装.

该结构采用优化截面设计进行工程设计, 高强度结构钢确保在振动锤作业过程中保持平稳控制的同时,具有强大的抗变形能力。加固的承载区域有助于均匀分散振动力,从而提高抗疲劳性和使用寿命。

每台CX800打桩臂 定制建造 根据实际工作条件、锤头规格和现场要求,为重型建筑工程提供可靠且适应性强的打桩解决方案。

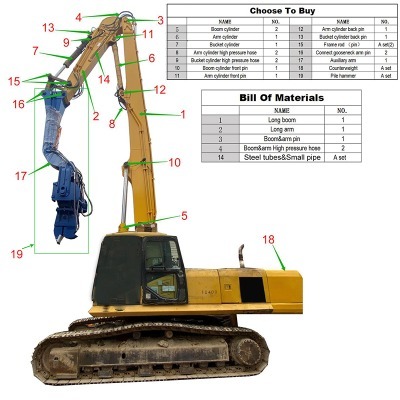

▎主要特点

动臂几何形状和安装尺寸与 CX800 挖掘机的输出和稳定性要求相匹配。

关键受力区域经过加固,以承受长时间的高频振动。

支持大型地基工程中常用的各种液压振动锤。

优化的结构对齐有助于操作人员在安装过程中保持桩的垂直度。

液压管路布置可根据不同的施工现场布局和维护习惯进行配置。

▎配置情况

▎钢切割

切口平整,以确保钢板切割的精度。

▎沟槽焊接

焊接前,我们使用大型铣床对钢板边缘进行铣削(锥形加工)。这样焊接就能深入钢板内部,使结构具有更高的性能。

采用轨道焊接机进行焊接,并在拐角和加固处进行手工加固和焊接。

我们的吊臂和臂架采用大型焊接箱形结构,高应力区域采用厚板或多层板材。

内部加固板也使其更加坚固。

▎大型镗床——端镗

加工效率更高,精度更好,产品质量和劳动效率都得到了极大的提高。

▎工件表面处理——喷丸处理

大型喷丸机的细小钢球用于冲击工件表面,去除钢板表面的锈迹和细小杂质,使工件表面呈现原有的金属光泽,并提高底漆的附着力。

▎底漆和面漆处理

使用与挖掘机原厂相同的油漆进行喷涂,以确保颜色一致。

▎高压硬管及管道弯曲处理

1.摩擦焊接法兰和油缸——采用机器高速摩擦焊接,效率更高,避免了人为的假焊和气泡。

2. 自动弯管机 - 采用数控技术控制管道弯曲程度,自动弯曲无缝钢管,精度更高。

▎油漆/包装/运输服务

1.油漆颜色与品牌挖掘机工厂一致(颜色可定制),采用优质油漆,使产品更加精致美观。

2. 我们使用拉伸膜包装产品。(需注意:包装框架为三层胶合板木框)

3. 我们与中国多家船运公司合作多年,运输服务和效率都非常好。(推荐FOB/CIF/CNF条款)

▎证书及工厂历史

我们最初隶属于一家在华运营的新加坡私营工厂。我们始终专注于挖掘机行业,积累了丰富的数据和制造经验。我们为全球多个国家的经销商提供专业的挖掘机配件。我们坚持质量第一,注重细节,因此赢得了众多品牌经销商的信赖,成为他们的合作伙伴。

(为保护客户隐私,信息和照片不会显示)

材质:Q355B主要参数模型CAT350动臂长度9.6M臂长4.2米锤头臂XM手臂油缸类型外贸类型(国外)配重X吨

材料:Q355B主要参数模型CX380C繁荣长度10.5 米臂长5米臂缸类型外贸类型(外国)配重7吨

材料:Q355B主要参数模型CAT336繁荣长度9.5米臂长5.5米臂缸类型外贸类型(外国)配重7吨

材质:Q355B主要参数模型ZX470动臂长度11.5M臂长5.3M手臂油缸类型外贸类型(国外)配重不需要

材质:Q355B主要参数模型SH460HD动臂长度10.5M臂长4.5M手臂油缸类型外贸类型(国外)配重不需要

材料:Q355B主要参数

材料:Q355B主要参数

主要参数型号CAT335类型打桩挖掘机长度22.5米材料Q355B 或 Q690D健康)状况新的臂缸式外贸类型(外国)规格原厂设备制造商桶大小选择认证CE、ISO9001:2000

我们7*24小时在线解答您的所有问题

新闻快讯

新闻快讯通过订阅我们的邮件列表,您将始终从我们这里获得最新的新闻和更新。